Last time on Pinball Aficionado we were looking at a routed Spiderman that my buddy had picked up and decided to shop. We followed a plan of attack where we had taken photos of everything, then disassembled the playfield components, and kept them organized in clusters around the room. We then took a breath ("phew!), started cleaning the playing surface (and all the components) with alcohol, and then after everything was clean, we went and polished the playfield, and some of the components with Novus 2.

|

| Cleaning up that playfield! ("Spiderman......Spiderman...Does whatever a spider can".....oh sorry :D) |

|

| Working on a pop bumper... |

|

| Pop bumper progress..... |

Now after all that (about 6 hours in), the real fun begins....REASSEMBLY!!! (Duh duh duuuuuuuuuuuuuuuuuuuuuuuuuuuuuuuh!!!) This is typically the cringe-worthy moment, the "put up or shut up" the moment that you gotta put everything back in order and when you're done it all has to work! The thing about modern pinball machines, is that typically, due to their complexity, parts have to be reassembled in a specific way. You can't just put stuff in when you want to, things are placed with other things in mind, and if it's done out of order, certain things will no longer fit properly (can't screw in a plastic after a ramp is in if that plastic belonged below it for example).

I should take this time to mention that during the cleaning portion, we took a look at the playfield underside and cleaned and checked the major components down there (magnets, coils, solenoids) and replaced or repaired any worn parts. My buddy also insisted on installing LEDs, and we did that when all the above board parts had been removed.

During assembly is where all the photos came in handy (note to self, video can be good too). I took so many pictures during the breakdown that we were able to piece it together backwards and know what components went off first, then second, etc. If you know the order of how you took it all down, then it's easier, as most parts only fit in their respective spot on the game (duh! that's how they're designed). So using the photos, having all the newly cleaned parts organized around the work area, and using the game's manual schematics as a safety net, we went and reassembled it.

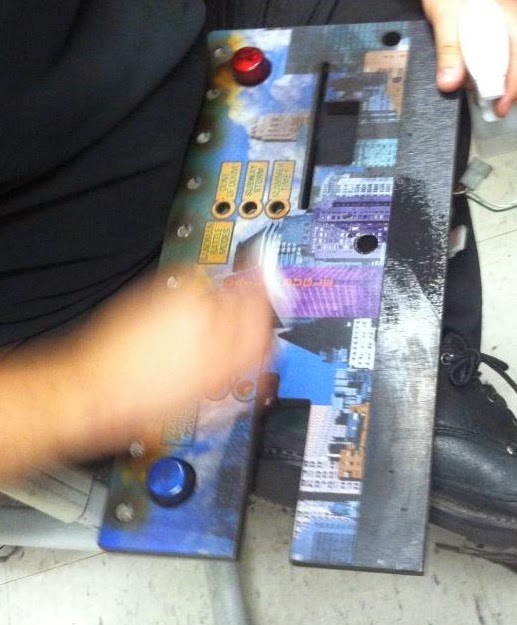

|

| Installing LEDs................ |

During assembly is where all the photos came in handy (note to self, video can be good too). I took so many pictures during the breakdown that we were able to piece it together backwards and know what components went off first, then second, etc. If you know the order of how you took it all down, then it's easier, as most parts only fit in their respective spot on the game (duh! that's how they're designed). So using the photos, having all the newly cleaned parts organized around the work area, and using the game's manual schematics as a safety net, we went and reassembled it.

........................................."7 hours later".........................................

Yeah!!!!!!!!!!!!!!!!!!!!!!!!

So the moment of truth arrived and it was time to turn the game on, and..........................IT WORKED!

We played a game and it was great. I guess you could say.........THE DAY WAS SAVED!!!!!!

My buddy later decided to operate the game on his route at Arcade Odyssey, in Miami FL. You can see two videos (Game View and Demo) of this very Spiderman below:

View of the restored, working game today

Game being played...

Fun facts: the total shop job took just over 13 hours, which we accomplished during 4 sessions. A few playfield plastics were broken but we found replacements, all the major underside mechanisms worked after they were cleaned, and once it was finished, the game was good as new. Some people online have given grief as to the durability of Stern games, but I gotta say, in this case Spiderman seems a very durable title that cleaned up very well, one might even say......SUPER well! (har har har) ;)

Till next time!!!